Cold Core Technology achieves successful mass production of non-airtight Micro-TEC

News Introduction: Cold Core Technology has successfully developed high-performance anti-dew point corrosion-resistant protective materials, effectively solving the technical problem that TEC devices cannot meet the requirements of non-airtight use environments.

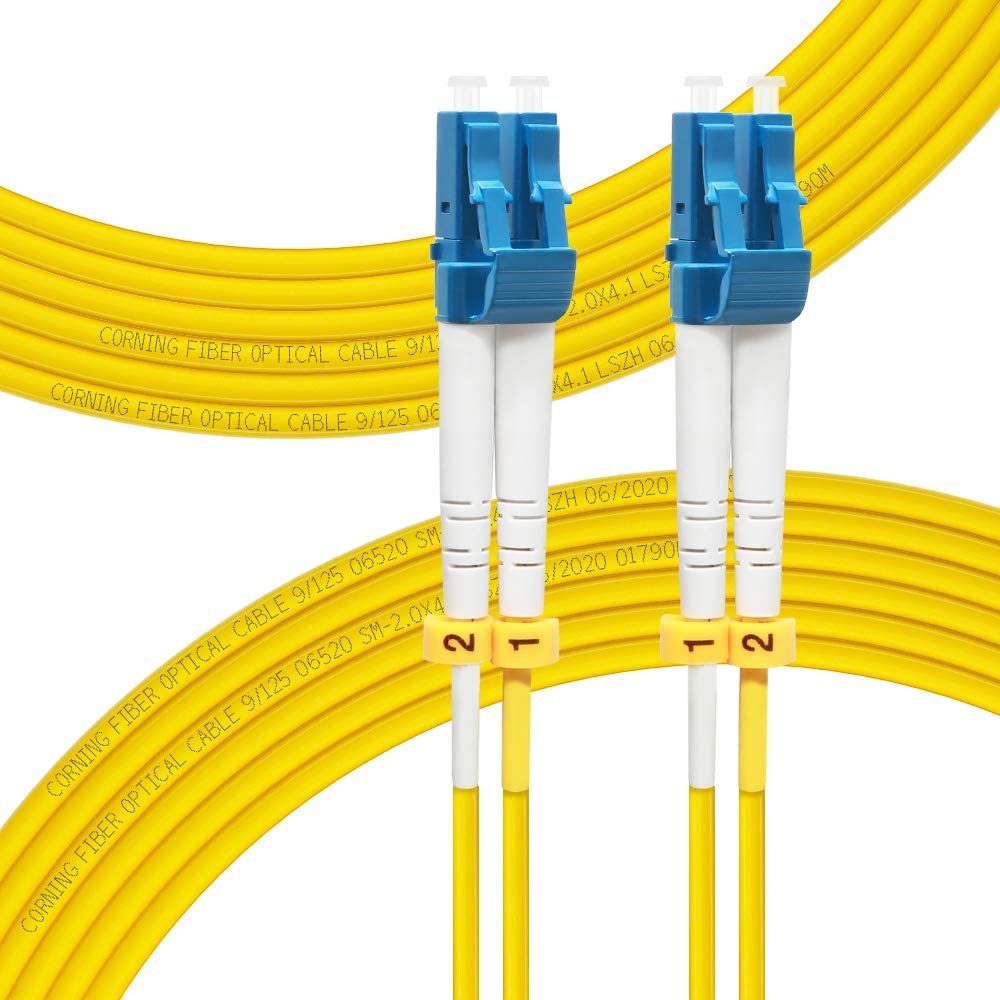

In the field of optical communication, the thermoelectric cooling chip Micro-TEC is generally packaged with the optical chip and used in an inert gas environment. However, in recent years, the demand for Micro-TECs that can be used in non-airtight environments has increased significantly due to the need to control costs and special operating conditions. Traditional bulk large-size TECs mostly use silica gel/epoxy resin as sealing materials. However, due to the large difference in elastic modulus between the packaging material and the substrate, the heterogeneous interface is easily affected by thermal shock and cracks during use, resulting in TEC devices. Unable to meet the requirements of non-airtight use environment. Recently, Cold Core Semiconductor Technology Co., Ltd. has successfully developed a high-performance anti-dew point corrosion-resistant protective material, which effectively solves the above-mentioned sealing technical problems.

When sealing a TEC device with silicone/epoxy, generally only the surrounding edges of the device are sealed, and there is a certain risk in terms of sealing reliability. Once a gap or aging occurs at any edge seal, the sealing effect will be significantly deteriorated, and water vapor can enter the interior of the TEC device through the gap or aging wound, which will cause corrosion failure of the device.

Compared with silica gel/epoxy resin, the protective material developed by our company can penetrate into the tiny space inside the Micro-TEC device to form a uniform, conformal, continuous, dense and low elastic modulus protective layer, which effectively prevents water vapor from affecting thermoelectricity. It has excellent electrical insulation, acid and alkali corrosion resistance, cold and thermal shock resistance, low thermal conductivity, and can be used for a long time under harsh working conditions.

Cold Core Semiconductor Technology Co., Ltd. mainly develops, produces and sells high-end Micro-TEC products, including aerospace-grade, JG-grade, industrial-grade, and commercial-grade Micro-TEC and corresponding high-performance thermoelectric raw materials. Since its establishment, the cold core company has always adhered to independent innovation and overcame difficulties, committed to improving the comprehensive performance of Micro-TEC devices, building an internationally advanced Micro-TEC industry chain, and serving the country with innovation and industry!

Analysis: What does it mean for Nokia to supply Microsoft with data center switches?

Analysis: What does it mean for Nokia to supply Microsoft with data center switches?

Interview with MRSI, Mycronic: MRSI has witnessed the rapid development of China's optoelectronics industry for 20 years

Interview with MRSI, Mycronic: MRSI has witnessed the rapid development of China's optoelectronics industry for 20 years

IQE Releases World's First Commercially Available 200mm (8-inch) VCSEL Wafer

IQE Releases World's First Commercially Available 200mm (8-inch) VCSEL Wafer

Vertical integration tempers high-quality, differentiated fiber laser solutions

Vertical integration tempers high-quality, differentiated fiber laser solutions